A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y / M A R C H 2 0 1 7

1 8

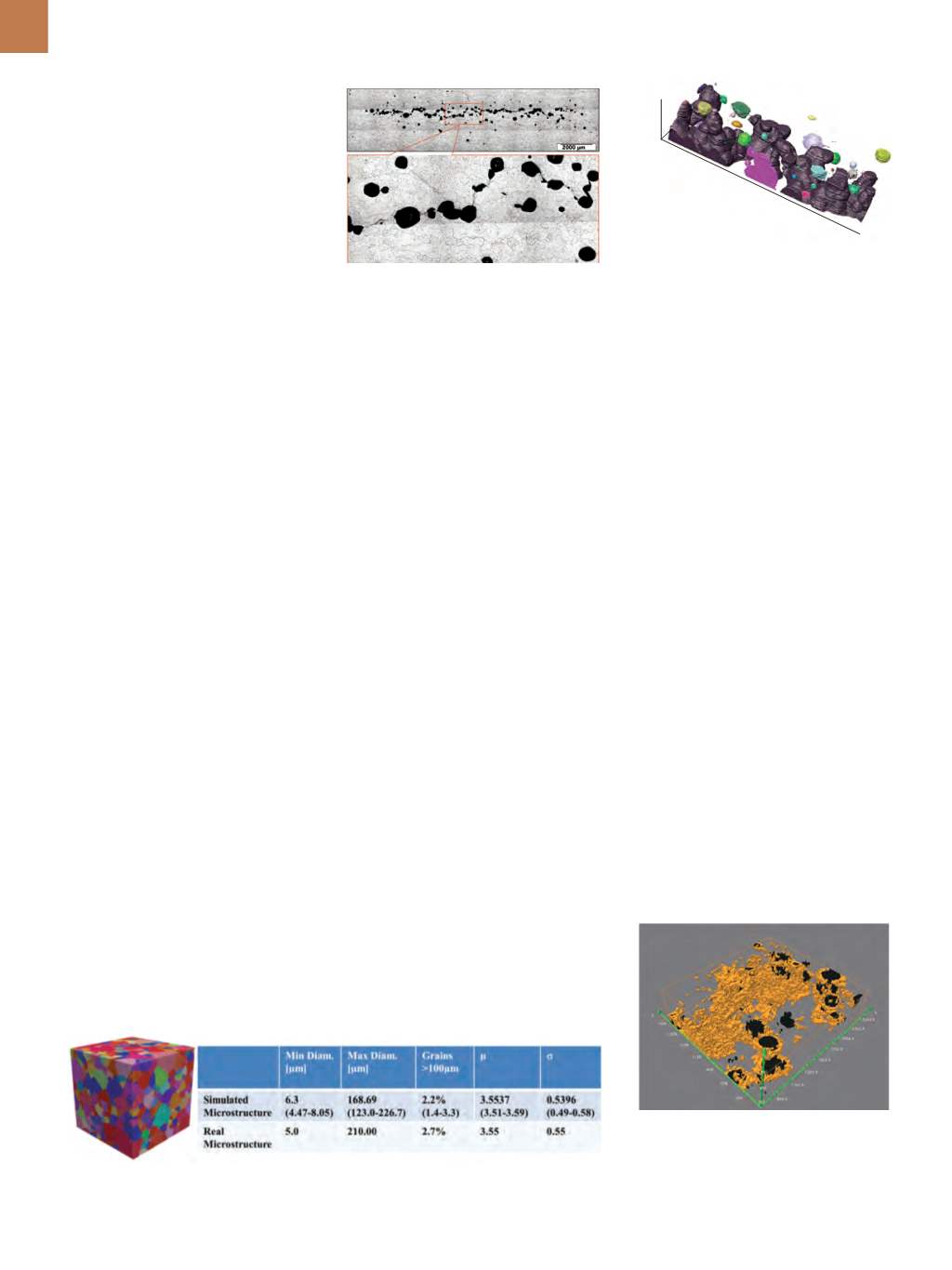

Synthetic microstructures were

generated for a rolled and annealed

high-purity tantalum material from

Cabot Corp. The plate composition was

high purity, with ppm contents of <50 O,

10 N, 10 C, and 5 H. EBSD analysis was

performed with a step size of 1.0 µm

on a Phillips XL30 FEG SEM, using the

TSL data collection and analysis soft-

ware, encompassing tens of thousands

of grains, capturing more than 100,000

boundary segments. Grain size, orien-

tation distribution function (ODF), and

grain boundary misorientation param-

eters were determined using the TSL

orientation imaging microscopy (OIM)

software. Based on statistics collect-

ed on the tantalum material including

grain size and morphology, and ODF, a

statistics file was generated and used

within DREAM.3D to generate digital

microstructure volumes. An example

of digitally generated tantalum materi-

al is shown in Fig. 2. A large number of

such volumes were created and it was

confirmed that the statistics are similar

to the starting material from which the

experimental data was collected.

The method provides an unlimited

supply of digital microstructures, which

are statistically representative of the

original material. Synthetic volumes are

surface meshed to enable moving mod-

els into FEM or other simulations. Inter-

pretation of physical behavior is per-

formed by comparing experimental to

calculated free surface velocity respons-

es by including hypothesized mech-

anisms within the theoretical model

used to conduct the simulations.

INVESTIGATING DUCTILE

DAMAGE

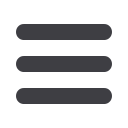

As mentioned previously, nucle-

ation of damage is a statistical pro-

cess where 3D distribution of sizes and

strengths of defects, local heteroge-

neous polycrystal stress states, and

poorly understood atomistic level phys-

ical mechanisms of damage nucleation

play a fundamental role. Figure 3 shows

void damage in a tantalum sample

tested in a plate impact gas gun exper-

iment; microstructure characterization

indicates that voids nucleate at specific

microstructural features.

Serial sectioning and volumetric

reconstruction of void-based damage

in the sample enables quantification of

the true size, shape, and distribution of

both individual microstructural features

and their local neighborhoods. This

reveals hidden connectivity between

features (Fig. 4), insight unobtainable

from 2D-based stereological approach-

es. The 3D reconstruction also indicates

that the amount of void damage varies

fromsection to section between 3%and

15%. Void fraction variation is assumed

to depend on the spatial distribution of

damage prone microstructural features

in the material.

Optical microscopy reveals materi-

al damage such as voids and cracks or

retained microstructural features, but

it fails to indicate how the rest of the

material is affected by the deformation

processes. EBSD data can be processed

to extract orientation image maps and

plots enabling visual representation

of orientation related aspects of the

deformed microstructure. Local mis-

orientation can be characterized using

a kernel misorientation approach. Ker-

nel average misorientation (KAM) maps

are now a standard method to indicate

relative differences in crystallographic

orientation between neighboring points

in a sample. KAMs was applied to quali-

tatively evaluate localized plastic strain

in the material. Generally, KAM is high-

er in deformed regions or grains. For

the specimen presented here, KAM was

calculated to the 5th neighbor, with

a maximum misorientation of 6˚. Re-

gions with less than 2˚misorientation

were considered undeformed. The 3D

reconstruction of KAM maps obtained

from EBSD (Fig. 5) in shocked tantalum

reveals contiguous and complex plastic

linkages in 3D. Therefore, the micro-

structure not only must be viewed as a

3D concept, but the events and features

related to deformation and damage

also must develop in 3D.

Fig. 3 —

Void damage in a tantalum

sample tested in a plate impact gas gun

experiment.

Fig. 2 —

Comparison of statistics from a digitally generated tantalummicrostructure containing

1500 grains to the real material.

Fig. 4 —

3D reconstruction of void distribu-

tion in shocked tantalum.

Fig. 5 —

3D reconstruction of kernel aver-

age misorientation (KAM) maps in shocked

tantalum. Black and orange represent void

damage and deformation affected material,

respectively.

Cavitation, linkage by localized shear, and void coalescence

500

1000

1500

2000

x [μm]

400

300

200

100

Z [μm]

200

Y