A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y / M A R C H

2 0 1 7

1 5

SMALL SCALE LITHIUM

FEATURES SURPRISING

STRENGTH

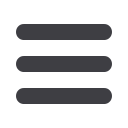

A team of researchers from

Caltech, Pasadena, Calif., and Carnegie

Mellon University, Pittsburgh, mea-

sured the strength of lithium metal at

the nano- and microscale, a first that

could ultimately lead to improved lith-

ium-ion battery performance. Using a

special vacuum chamber at Caltech,

the team formed pillars of single-crystal

lithium a few micrometers tall and just

a few nanometers to micrometers in

diameter. They discovered that at this

size, lithium is up to 100 times stronger

than indicated by previous measure-

ments at a larger scale. Additionally,

researchers found that the stiffness of

lithium dendrites—needlelike branch-

ing structures that advance into a

battery, causing it to short-circuit or

even explode—varied by as much as a

factor of four according to their crystal-

lographic orientation.

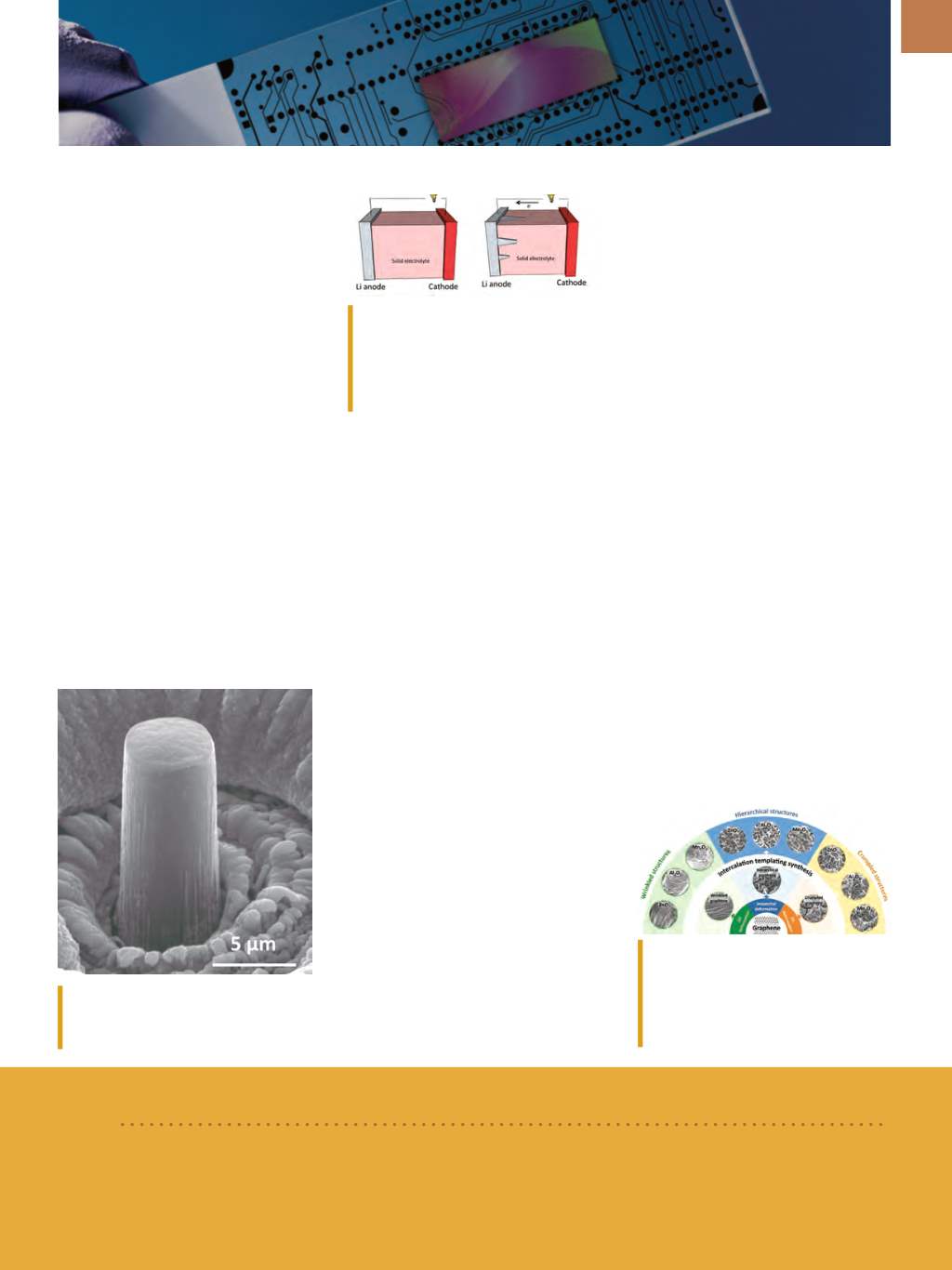

Until now, attempts to physically

curb the growth of lithium dendrites

have involved a solid electrolyte sand-

wiched between the cathode and anode

to serve as a physical barrier; however,

the electrolytes used thus far have not

been able to withstand the force of the

growing dendrites. Now that research-

ers know what they’re up against, a

stronger solid electrolyte can be devel-

oped to keep the lithium dendrites in

check.

caltech.edu, cmu.edu.

NEW METAL-OXIDE FILMS

PATTERNED ON GRAPHENE

Researchers from Brown Univer-

sity, Providence, R.I., developed a new

method for making ultrathin textured

metal-oxide films that have improved

properties as catalysts and electrodes.

The scientists placed stacks of wrinkled

graphene sheets in a water-based solu-

tion containingpositively chargedmetal

ions. The negatively charged graphene

pulled the ions into the spaces between

the sheets, and the particles bonded

together, creating thin sheets of metal

that followed the wrinkle patterns of

the graphene. When the graphene was

oxidized away, the texturedmetal-oxide

film remained. The process works with

a variety of metal oxides—zinc, alumi-

num, manganese, and copper oxides—

which are too stiff to be textured with

the methods the team previously devel-

oped to deform graphene films.

In the experiments that followed,

researchers demonstrated improved

properties of the new films. Wrinkled

manganese oxide, when used as a bat-

tery electrode, had a charge-carrying

capacity four times higher than a planar

sheet, and crumpled zinc oxide filmwas

four times more reactive than a planar

film in a photocatalytic reaction—re-

ducing a dye dissolved in water under

ultraviolet light. The process represents

more than just bolstered performance,

according to Po-Yen Chen, a postdoc-

toral researcher. “Based on what we

learned from making the metal-oxide

films, we can start to think about using

this method to make new 2D materi-

als that are otherwise unstable in bulk

solution,” he explains. “With our con-

finement method, we think it’s possi-

ble.

” brown.edu.NANOTECHNOLOGY

BRIEF

The world nanomaterials market is forecast to reach $55,016 million by 2022, registering a CAGR of 20.7% from 2016 to

2022, according to a new report available from

Report Buyer,

London. Heavy investment in R&D activities by

government organizations is expected to propel market growth.

reportbuyer.com.A micrometer-sized pillar of lithium.

Images courtesy of J. Greer Laboratory/

Caltech.

Diagrams of a lithium-ion battery. When

the battery is connected and charge

is flowing (at right), small needles of

lithiummetal grow, which can destroy

the battery.

Using graphene sheets as tiny templates,

researchers developed a method of

making metal-oxide films with intricate

surface textures. Courtesy of Hurt/Wong

Labs, Brown University.