A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y / M A R C H

2 0 1 7

2 3

TABLE 3—BINNING OF GRAIN AREAS BY G CLASS FOR 26-1 FERRITIC STAINLESS STEEL

G 1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

% 0

3.5 16.3 24.4 20.6 17.4 10.4 3.7 0.7 0.1 0.08 0.008 0.011 0.004 0.003

Area

No. grains ∑ grain areas, μm

2

Avg. grain area, μm

2

ASTM G, all grains

No. of G classes

339

804,976.1

2374.6

5.7

14

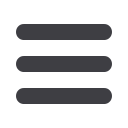

Fig. 6

—

Grain size distribution for 26-1 fer-

ritic stainless steel revealing non-Gaussian

grain size distribution, but without a clear bi-

modal, or duplex, grain size distribution. The

distribution covers 14 grain size classes with

a mean grain size of ASTM G = 5.7, which can

arbitrarily be divided into two classes with

47.1% of the grains having a mean grain size

of G = 3.7 and the balance with a mean grain

size of 6.5. A skew of 3.59 and kurtosis of

18.62 is non-Gaussian.

TABLE 4—BINNING OF GRAIN AREAS BY G CLASS FOR SC-19 AUSTENITIC STAINLESS STEEL

G 1

2

3

4

5

6

7

8

9

10 11 12 13 14 15

% 0

28.2 17.3 12.3 6.97 5.08 2.77 2.6 4.19 6.4 6.5 4.29 2.1 0.99 0.38

Area

No. grains ∑ grain areas, μm

2

Avg. grain area, μm

2

ASTM G, all grains

No. of G classes

3901

578,437.1

148.28

9.77

14

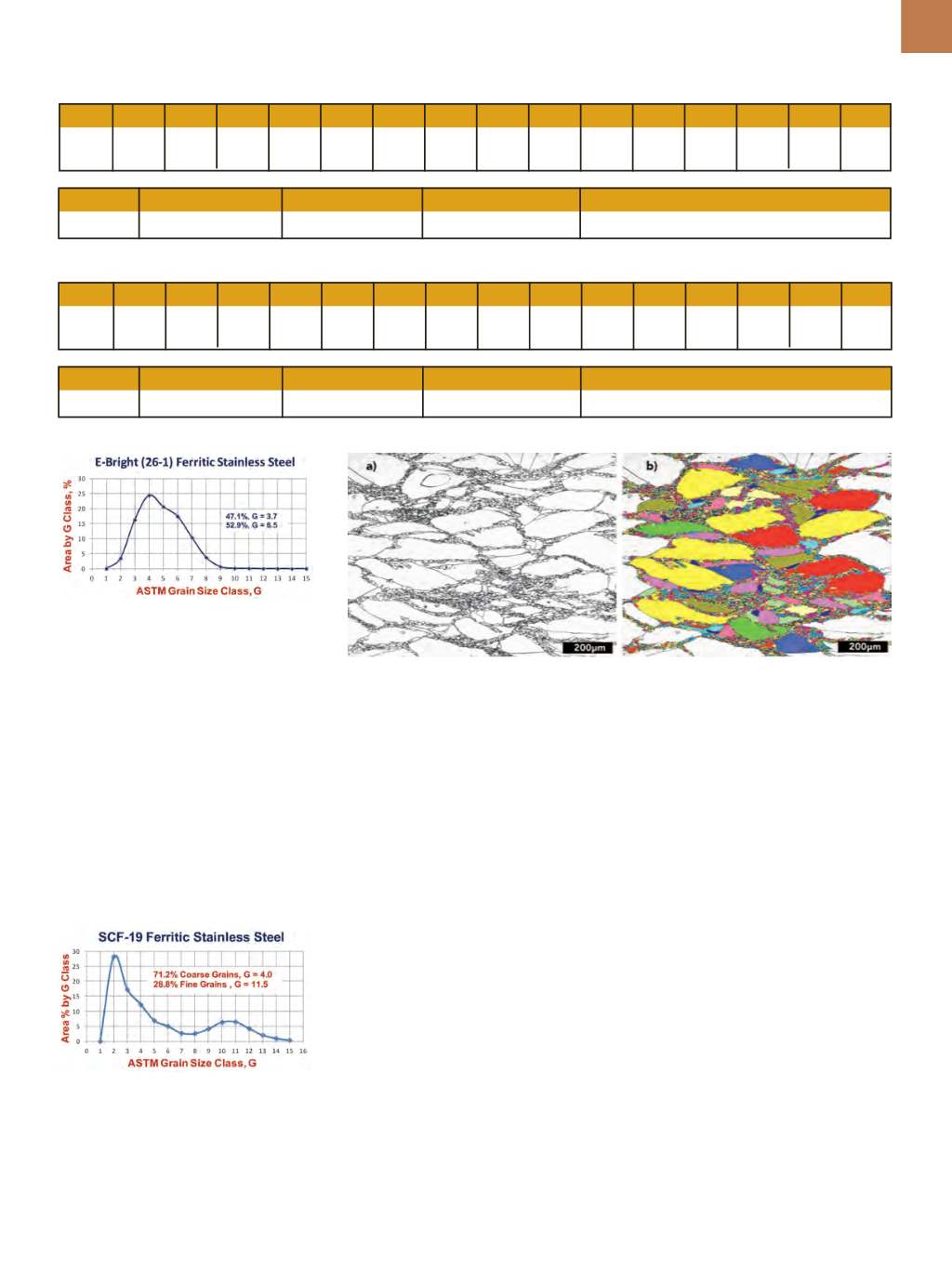

Fig. 8

—

Bimodal grain size distribution in

partially recrystallized SCF 19 austenitic

stainless steel covering 14 grain size classes

where the mean grain size of all grains is

9.77, although such a measure is of no value

due to the duplex grain size distribution.

the maximum value of 5 for a normal

distribution. The grain size distribution

curve with a slight hump to the right of

the maximum value is shown in Fig. 6.

The mean overall grain size is G = 5.7.

The distribution curve is not bimodal,

and although not justified, it could be

broken into two parts and calculated

that 47.1% of the grains have a mean

grain size of G = 3.7, while 52.9% have a

mean grain size of G = 6.5.

Example 3.

Figure 7 shows a bi-

modal grain size distribution called a

necklace distribution in SCF-19* auste-

nitic stainless steel. The specimen was

cold reduced 10% in thickness and solu-

tion annealed at just 900°C, while the

recommended solution annealing tem-

perature is 1180°C. Grain boundaries

were selectively electrolytically etched

using aqueous 60% nitric acid at 1 V

dc for 60 s (annealing twin boundaries

are not revealed using this etch and

voltage). Table 4 contains the area per-

centage of grains per G class, covering

14 G classes, for 3901 grains measured.

The skew for the distribution shown in

Fig. 8 is 16.96 and the kurtosis is 320.04,

a very high value. The distribution is

clearly bimodal with 71.2% of the grain

area having a mean grain size of G = 4

and 28.8% having a mean grain size of

G = 11.5.

~AM&P

*Note: E-Brite 26-1 is a registered trade-

mark of ATI Allegheny Ludlum. SCF-19

is a registered trademark of Carpenter

Technology Corp.

For more information:

George F.

Vander Voort is a consultant for Stru-

ers Inc., 24766 Detroit Rd., Cleve-

land,

OH

44145,

847.623.7648,

georgevandervoort@hotmail.com,

www.georgevandervoort.com.

Fig. 7

—

SCF 19 austenitic stainless steel with a bimodal necklace-type grain structure

due to partial recrystallization after cold working: (a) partially recrystallized grain structure

etched using aqueous 60% nitric acid at 1 V dc for 60 s (100×); (b) detection of grain areas by

image analysis.