A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y / M A R C H 2 0 1 7

2 2

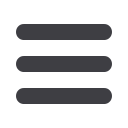

tint etched using Klemm’s I reagent at

a magnification of 100× (the magnifi-

cation bar was removed to make grain

area analysis simpler). Figure 2 shows

detection of grain boundaries by IA.

Boundaries can be eroded to one pix-

el width, with the image then inverted

to detect grain interiors. Each grain is

measured for its area, and the areas

are mathematically analyzed for skew

and kurtosis. Grain areas are ordered

from largest to smallest, and grain ar-

eas in each grain size class (as defined

in Table 1) are added and divided by the

total area of all grains measured and ex-

pressed as a percentage (Table 2). A plot

of these data (Fig. 3) has a kurtosis of

2.55 (close to a perfect normal Gaussian

distribution), and the data cover eight

ASTM G classes with an average grain

size of ASTM G = 6.66. Due to the nature

of the G calculation (Eq. 1), the distribu-

tion of % grain areas per G class versus

G reveals a normal distribution. By com-

parison, the x axis in Fig. 4a is a linear

scale of grain areas rather than G values,

and the distribution is now log-normal.

By using seven grain area classes rather

than 14 (Fig. 4b), the distribution curve

is smoother with less noise.

Example 2.

Figure 5a shows the

grain structure of E-Brite 26-1,* a ferrit-

ic stainless steel, etched electrolytically

using aqueous 60% nitric acid at 1 V dc

for 20 s. The structure exhibits areas of

banding with coarse and finer grains.

Figure 5b shows the detected grain ar-

eas measured by IA. Table 3 contains

measurement data by ASTM G class

covering 14 G classes. The skew is 3.59,

while the kurtosis is 18.62, well above

Fig. 1

—

Ferrite grain structure of a motor

lamination steel etched using Klemm’s I

reagent at a magnification of 100×

(magnification bar removed for grain area

measurements).

Fig. 3

—

Grain size distribution curve for

motor lamination steel revealing excellent

unimodal, Gaussian grain size distribution

with a mean ASTM grain size of 6.63, kurtosis

of 2.55, skew of 1.43, and a distribution

covering eight grain size classes.

Fig. 4a

—

Plotting grain areas (covering 14

grain size classes) for the motor lamination

steel instead of ASTM grain size (G) on the x

axis reveals a log-normal grain area distri-

bution rather than the unimodal Gaussian

distribution show in Fig. 3.

Fig. 4b

—

Seven grain classes plotted on a

linear scale using grain area rather than G.

Fig. 2

—

Detection of grain boundaries by

image analysis.

Fig. 5a

—

Example of non-Gaussian grain

size distribution containing regions of

coarse and fine ferrite grains.

Fig. 5b

—

Detection of grain interiors by

image analysis.

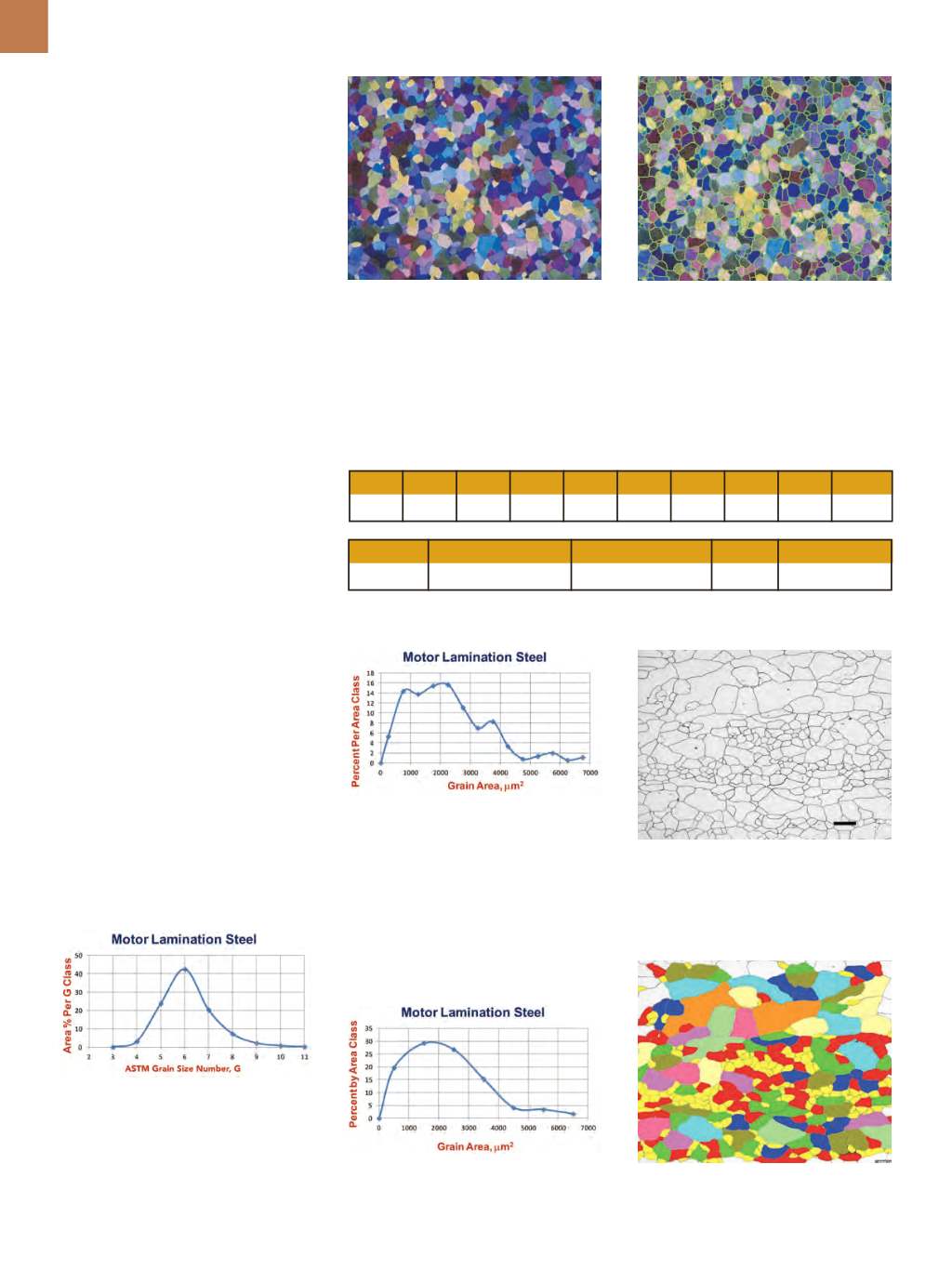

TABLE 2—BINNINGOF GRAINAREAS BYGCLASS FORMOTOR LAMINATIONSTEEL

G 3

4

5

6

7

8

9

10

11

% Area 0

3.19 23.76 42.53 20.25 7.21 2.19 0.76 0.12

No. grains ∑ grain areas, μm

2

Avg. grain area, μm

2

ASTM G No. of G classes

891

1,158,903

1300.68

6.63

8