A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y Y / M A R C H 2 0 1 7

2 6

when applied to propulsion systems.

In partial response to environmen-

tal concerns and growing regulatory

restrictions, the 1990s also involved

considerable research in replacing

hazardous materials. Materials and

processes for high velocity oxygen fuel

(HVOF) spray systems were optimized

to replace cadmium and chrome plat-

ing techniques. In addition, multiple

coating systems were transitioned, in-

cluding coating systems that utilize a

magnesium rich primer, which are used

to replace hazardous chromate coating

systems on large aluminum structures.

Establishment of the Coatings Technol-

ogy Integration Office facilitated this

research and helped establish ML as a

dominant international leader in test-

ing and developing coatings.

RECENT DEVELOPMENTS

The new millennium brought ex-

treme environmental and financial

challenges associated with multiple

conflicts operating in desert environ-

ments. ML responded in part by form-

ing multiple collaborative ML-industry

efforts including the Composite Afford-

ability Initiative and the Metals Afford-

ability Initiative (MAI). These programs

leveraged commercial and military re-

sources to further accelerate develop-

ment of new technologies. In particular,

they provided tremendous transitions

for new materials including thin walled

titanium castings for C-17 structures,

718+ nickel alloys for high temperature

turbines, Mondaloy nickel alloys for

rocket applications, and aluminum be-

ryllium for low density satellite applica-

tions and high stiffness optical control

structures. The current MAI program

continues to provide a vital research

link between major equipment man-

ufacturers and government research

personnel.

More recent research involves the

use of biotechnology to better under-

stand how biological organisms, such

as pit viper snakes or melanophilia

beetles, sense thermal or infrared en-

ergy. Scientists have begun using these

biologically inspired systems to devel-

op new materials, including the use of

spider silk technology for high strength

composite fibers. Further, researchers

have successfully developed flexible

materials that allow wearers to moni-

tor their physiological response in real

time using unique biological sensors.

These advances promise to revolution-

ize personnel assessment capabilities.

Flexible electronics and materials have

also enabled new solar panel energy

technologies and communication de-

vices for satellites and airplanes.

ML is known worldwide for pio-

neering work on defining the atomic

structure of metallic glasses. This fun-

damental knowledge has accelerated

discovery of new bulk metallic glass-

es and provides a foundation for un-

derstanding the unique properties of

this class of amorphous materials. ML

researchers were the first to use the

multi-principle element alloying phi-

losophy to intentionally devise a new

family of high entropy alloys (HEAs),

based on refractory elements, for high

temperature structural materials. Re-

search groups around the world are

now studying refractory HEAs and oth-

ers have followed this lead by defining

newHEA families for other applications,

including lightweight structural and

low cost catalytic varieties.

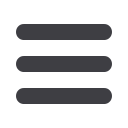

Many advances in developing

complex microstructures have been de-

veloped within ML, including work on

Mo-Si-B-X alloys for high temperature

oxidation applications, metal matrix

nanocomposites reinforcedwith carbon

nanotubes and graphite nanoplatelets,

titanium carbide reinforced nickel for

solid lubricating fracture-resistant com-

posites, and numerous titanium alloys

reinforced with boron additions, among

others. Two examples are shown in

Fig. 4. For example, ML has helped de-

velop and transition oxide/oxide ce-

ramic matrix composites currently in

use on turbine engine applications, and

high temperature silicon carbide/sili-

con carbide materials that are nearing

certification.

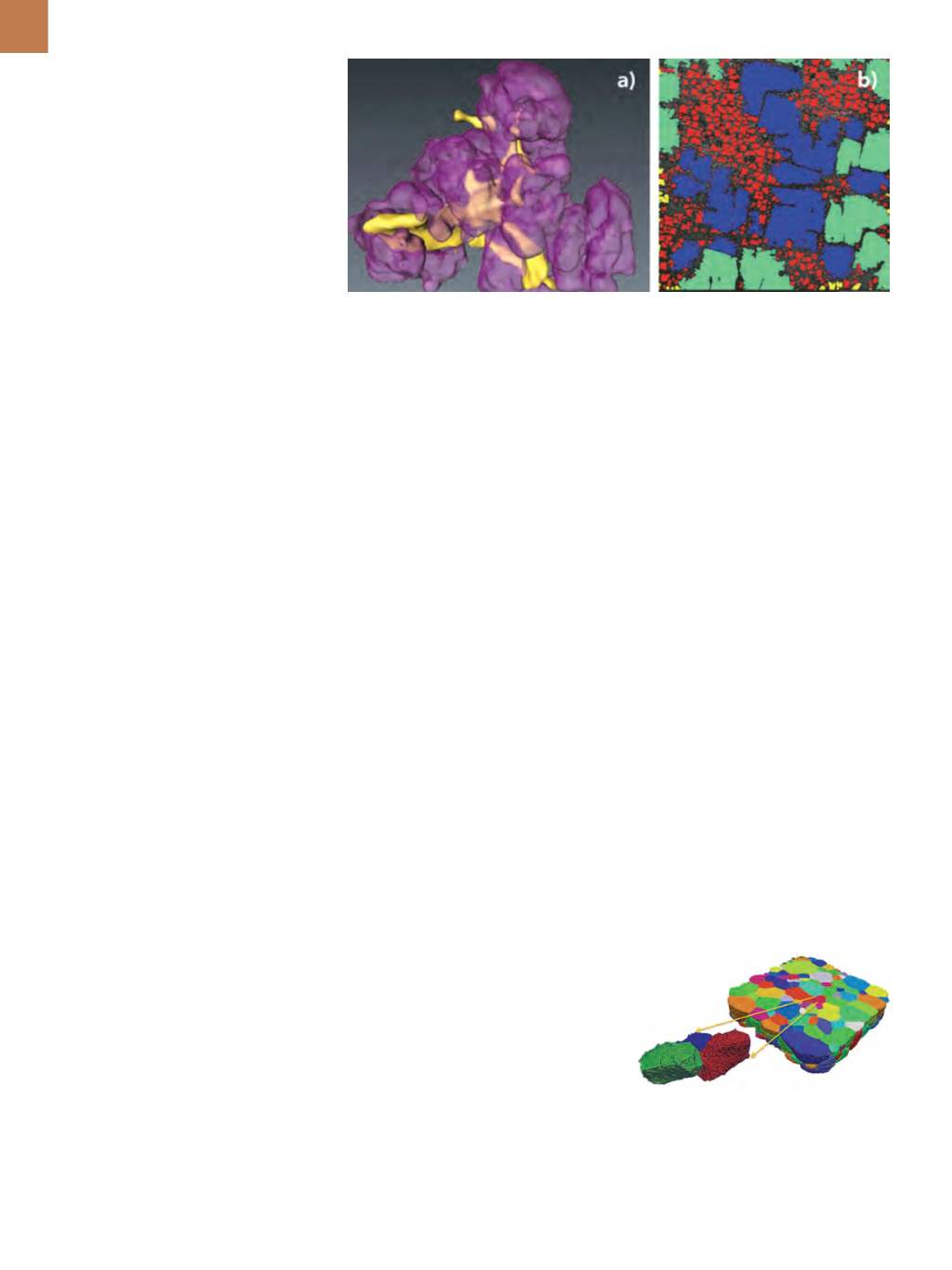

Current research involves precip-

itation strengthened cobalt alloys for

turbine disk applications, improved ce-

ramic and metal matrix composites for

potential hypersonic applications, and

development and modeling of additive

processing techniques, to name a few.

Advanced modeling approaches are

also being developed to simulate com-

plex microstructure interactions aimed

at improving the accuracy of deforma-

tion models used to predict mechanical

performance and certify new materials

for use in aerospace products. For ex-

ample, Fig. 5 shows a 3D reconstruction

Fig. 4 —

Advanced characterization techniques were employed to develop and characterize

newmicrostructures including (a) titanium nitride (yellow) in a graphite matrix (purple), and

(b) tertiary

γ

’ evolution in nickel alloys. Different colors represent different structures within

each image.

Fig. 5 —

3D reconstruction of metallic ma-

terial developed using advanced synchro-

tron techniques to identify individual grains

and grain texture information.