A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y / M A R C H 2 0 1 7

8

METALS | POLYMERS | CERAMICS

SOME LIKE IT HOT

A new record was set for the world’s

most heat resistant material by re-

searchers from Imperial College Lon-

don, UK. Using their new laser heating

technique, the team discovered that

hafnium carbide melts at a blistering

3958°C—the highest melting point ever

recorded for any material. Research-

ers applied their method to HfC and

another refractory ceramic, tantalum

carbide, as individual compounds as

well as in mixed compositions. They

discovered that while the melting point

of Ta0.8Hf0.20C was consistent with

previous research at 3905°C, each indi-

vidual compound exceeded previous

records, with TaC melting at 3768°C.

Until now, technology to test the melt-

ing points of these compounds was not

available. This work paves the way for

both materials to be used in more ex-

treme environments, such as fuel clad-

ding in nuclear reactors or heat shield-

ing for next-generation hypersonic

space vehicles.

www.imperial.ac.uk.

COMPOSITE TECHNOLOGY

GETS CONDUCTIVE

A team of researchers from the

Universities of Surrey and Bristol, UK,

and Bombardier, Canada, demonstrat-

ed that growing carbon nanotubes on

the surfaceof carbon fibers incomposite

materials significantly enhances their

electrical and thermal conductivity.

The discovery could provide significant

benefits in the aerospace industry, from

enhancing de-icing to lightning protec-

tion. “The aerospace industry still relies

on metallic structures, in the form of a

copper mesh, to provide lightning strike

protection and prevent static charge

accumulation on the upper surface

of carbon fiber composites,” explains

Thomas Pozegic, research associate at

Bristol’s Advanced Composite Centre

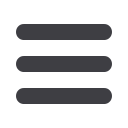

New research paves the way for more innovative heat shields. Courtesy of NASA.

BRIEFS

Largo Resources Ltd.,

Canada, will

produce, qualify, and sell its aero-

space-certified vanadium products

via

Glencore International AG,

Swit-

zerland, the exclusive offtaker of va-

nadium product currently produced

from the Maracás Menchen Mine.

High strength, low alloy vanadium

steels are rapidly replacing traditional

steels as demand surges for stronger,

lighter products for advanced appli-

cations.

largoresources.com.

Under a multiyear, $1 billion con-

tract launched in January,

Arconic,

New York, will serve as sole supplier

to

Airbus,

France, for specific appli-

cations, including some wing, fuse-

lage, and structural components. In

addition to its proprietary alloys, Ar-

conic plate products will be featured

on every Airbus platform, including

material from the company’s new

thick plate stretcher. Arconic’s most

significant share gain in the contract

is the A320 family, Airbus’ highest

growth program.

airbus.com, arconic.com.

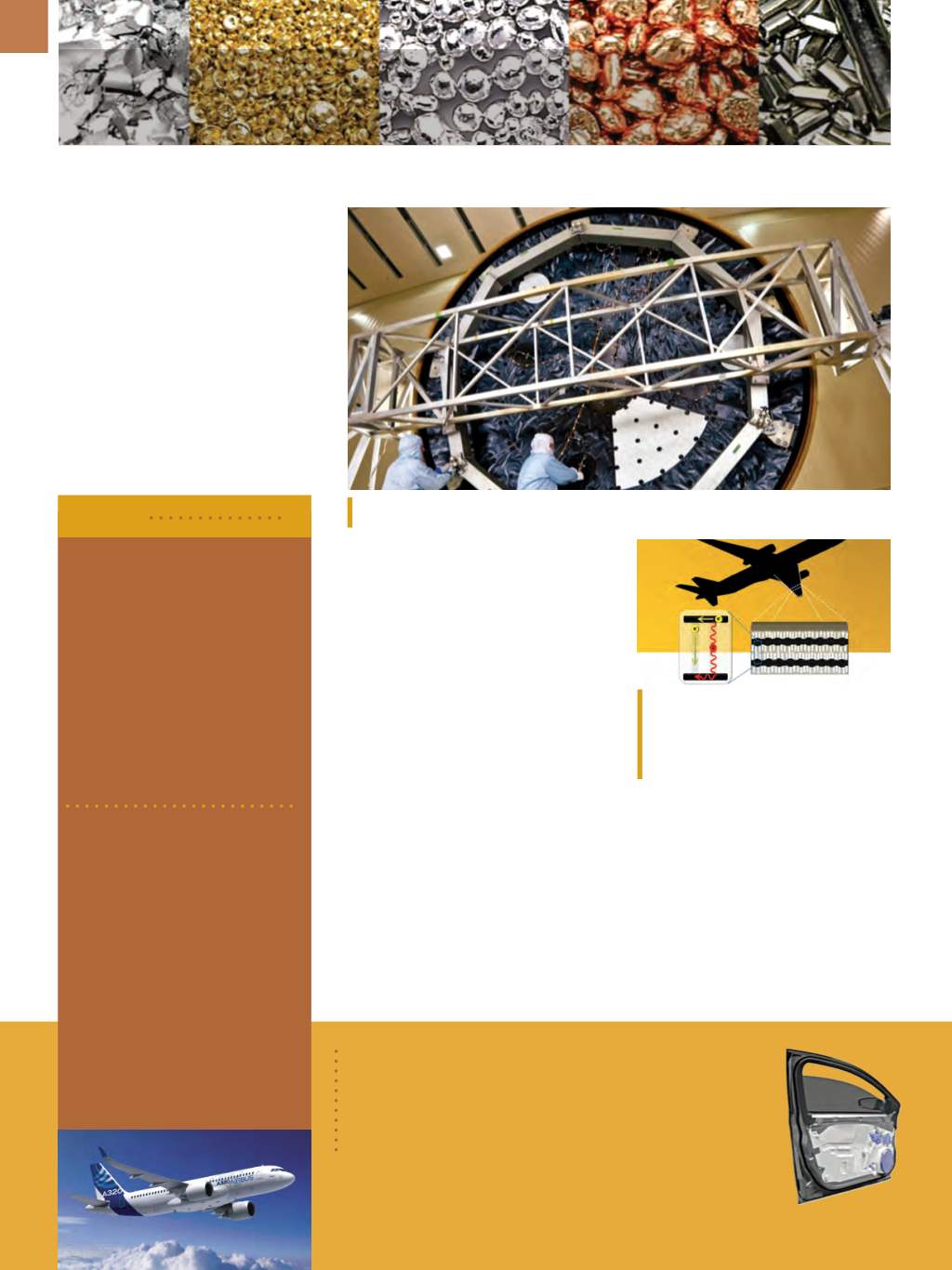

Vertically grown carbon nanotubes on

the carbon fibers (horizontal black lines)

enhance the composite’s electrical (e-)

and thermal (q) properties.

Magna International Inc.,

Canada, in cooperation with the

U.S.

DOE,

Washington, and partners

FCA US,

Auburn Hills, Mich., and

Grupo Antolin,

Spain, developed a new, ultralight door architec-

ture that achieves 42.5% mass savings compared to today’s aver-

age production door. Themodule could be applied to roughly 70%

of the light vehicle market.

magna.com.

Airbus A320

Ultralight door module achieves 42.5%mass savings.