A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y / M A R C H 2 0 1 7

6

MARKET SPOTLIGHT

AEROSPACE APPLICATIONS SPUR STEEL

FORGINGS MARKET

BERYLLIUM REBUTTAL

The letter in the July/August “Feedback”

department (“Beware of Beryllium”) was

misleading in two areas. First, it is no

secret that fine particles of beryllium can

restrict lung capacity. I worked in two dif-

ferent organizations processing beryllium

in the 1960s. In both facilities, employees

were toldmultiple times about the po-

tential hazards of fine berylliumparticles.

Since then, the EPA has formalized limits

on particles of this metal. As far as I know,

bulk berylliumhas never caused a health

issue. Second, it is not a gamble to use

beryllium for the space mirror project.

Berylliumhas been successfully used in

space since Telstar was launched in the

early 1960s. Berylliumhas unique combi-

nations of properties that outweigh the

requirements to use the metal safely.

George Meyer

BRING BACK STEEL

The recent piece on the decline of the in-

tegrated steel industry (“Metallurgy Lane,”

Nov/Dec 2016) was fascinating. I grew up

in Pittsburgh and left for the Air Force after

high school in 1974. I remember themill

jobs going away and watching the US Steel

building rise up frommy neighborhood,

Mt. Washington. What a lesson this article

paints. Having lost our place in steel, it is

a wonder howwe kept our place in the

world. It alsomakes one realize how close

we are to losing it in other industries.

We must bring steel back to the U.S.—

figure out how tomake it cleaner and

cheaper. More Nucors and determine how

to leapfrog the current technology for pro-

cessing steel fromore. This is low-hanging

fruit for jobs and security, and once we

figure out how tomake clean steel, we

can sell the plants to China and get the air

cleaned up. Thank you for publishing this

very interesting history lesson.

Carmen Vertullo

FEEDBACK

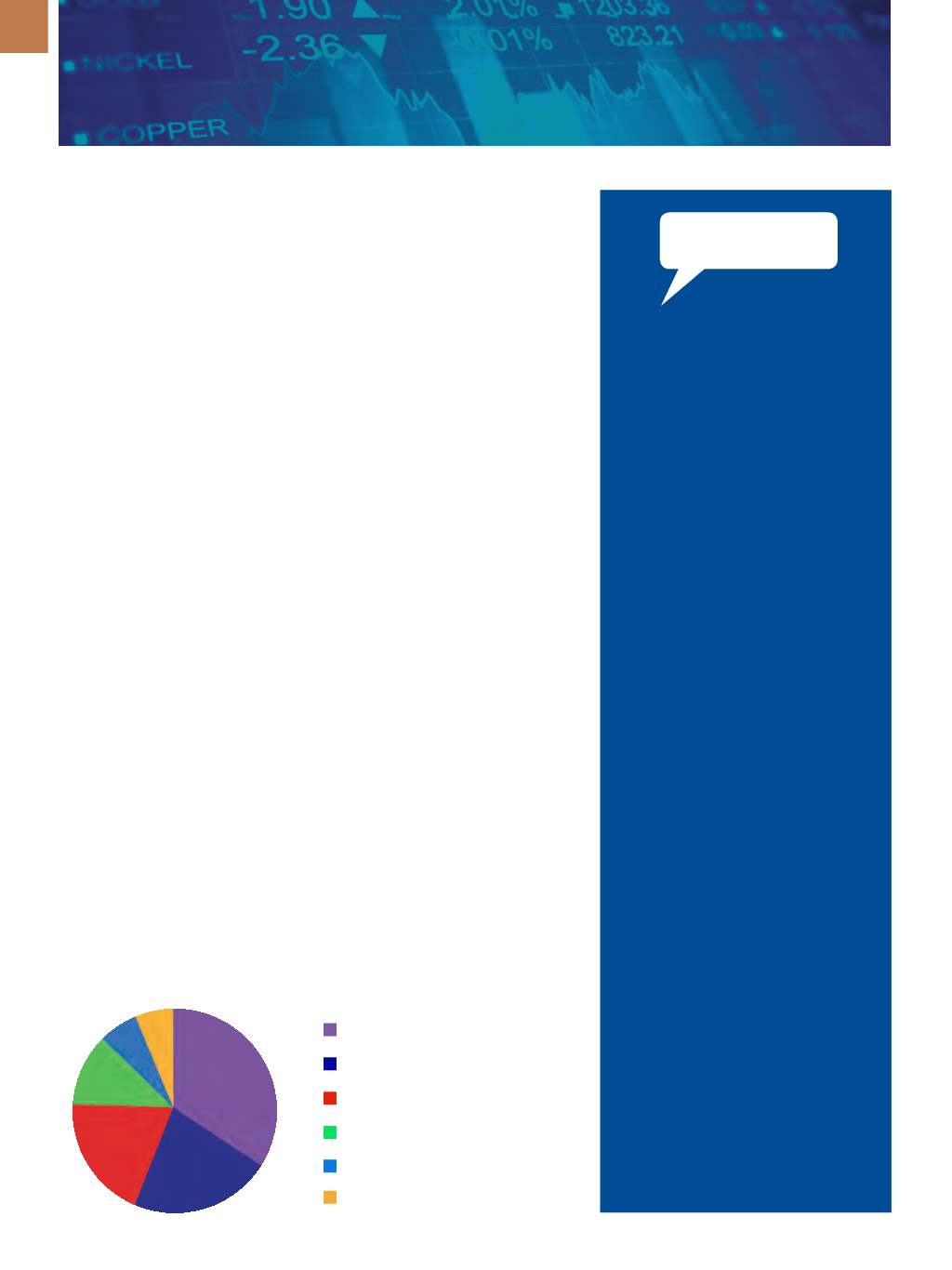

the world. The ability of stainless

steel to withstand chemical, phys-

ical, and electrical wear and tear is

the main factor responsible for mar-

ket growth. The high recyclability of

stainless steel is another factor driv-

ing demand. However, parts manu-

factured from aluminum and plastic

composites are expected to pose a

major threat to the growth of stain-

less steel forgings over the forecast

period.

Cold/hot forged parts are the

dominant product segment with a

market share of over 80% in 2015.

However, castings are the fastest

growing segment with an expected

CAGR of 4.5% from 2016 to 2024.

Sintered parts are a niche segment

within the market and feature prop-

erties such as electrical conduc-

tivity, translucency, and thermal

conductivity. Research and devel-

opment efforts involving sintered

products with enhanced strength

are expected to drive demand for

these products. The report includes

analysis of the stainless steel forg-

ings market in the U.S., Europe

(Germany, UK, France), Asia Pacific

(China, India, Japan), Latin Ameri-

ca (Brazil), and the Middle East and

Africa. For more information, visit

grandviewresearch.com.According to a new report from

Grand View Research Inc., San Fran-

cisco, demand for stainless steel

forgings in aviation applications is

expected to grow at a CAGR of 7%

from 2016 to 2024. The product’s

versatility with regard to size, shape,

and properties make it an ideal com-

ponent for the manufacture of bulk-

heads, wing roots and spars, hinges,

engine mounts, brackets, beams,

shafts, landing gear cylinders and

struts, wheels, brake carriers and

discs, and arresting hooks. In the au-

tomotive market, stainless steel forg-

ings are expected to grow at a CAGR

of 4.5% during the same period.

Increased demand for lightweight

forged products with enhanced

wear and tear resistance is driving

growth in the transportation sector.

“Stainless Steel Forgings Market Size

and Forecast by Product (Cold/Hot

Forged Products, Castings, Sintered

Parts), by Application (Building &

Construction, Industrial, Automotive,

Aviation, Consumer Goods), by Re-

gion and Trend Analysis from 2013 to

2024” discusses major trends taking

place in this market segment.

Global market size is valued at

$7.51 billion for 2015. Stainless steel

forgings demand is driven by grow-

ing manufacturing activity around

Industrial

Aerospace

Automotive

Building and construction

Consumer goods

Other

GLOBAL STAINLESS STEEL FORGINGS MARKET, BY APPLICATION, 2015

Source: Grand View Research Inc.