A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y / M A R C H

2 0 1 7

6 5

FEATURE

15

face within the computational domain. Each computa-

tional face is thus treated as a separate heat transfer zone

with the HTCs based on local conditions. Temperature-de-

pendent properties were used for both Inconel 718 and

Houghton 3420.

Temperature data were recorded during the simula-

tion process at each thermocouple location to compare

against experimentally measured values. The degree of

correlation at each location was based on the average

difference between the simulated and measured tem-

peratures over 1500 seconds of simulated time. This is

essentially the integrated area between the simulated and

measured cooling curves divided by total simulation time.

For the still oil case, average temperature deviations

ranged from 14.9° to 28.5°C, indicating that the simulation

provides a good representation of the actual quenching

behavior. For the thermocouples on the rimof the part, the

average spread of temperature data was 27.3°C, while the

average deviation between simulated temperature and

the mean of the six rim thermocouples was just 22.2°C. In

other words, the correlation of the simulation was within

the variation band for the actual process.

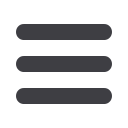

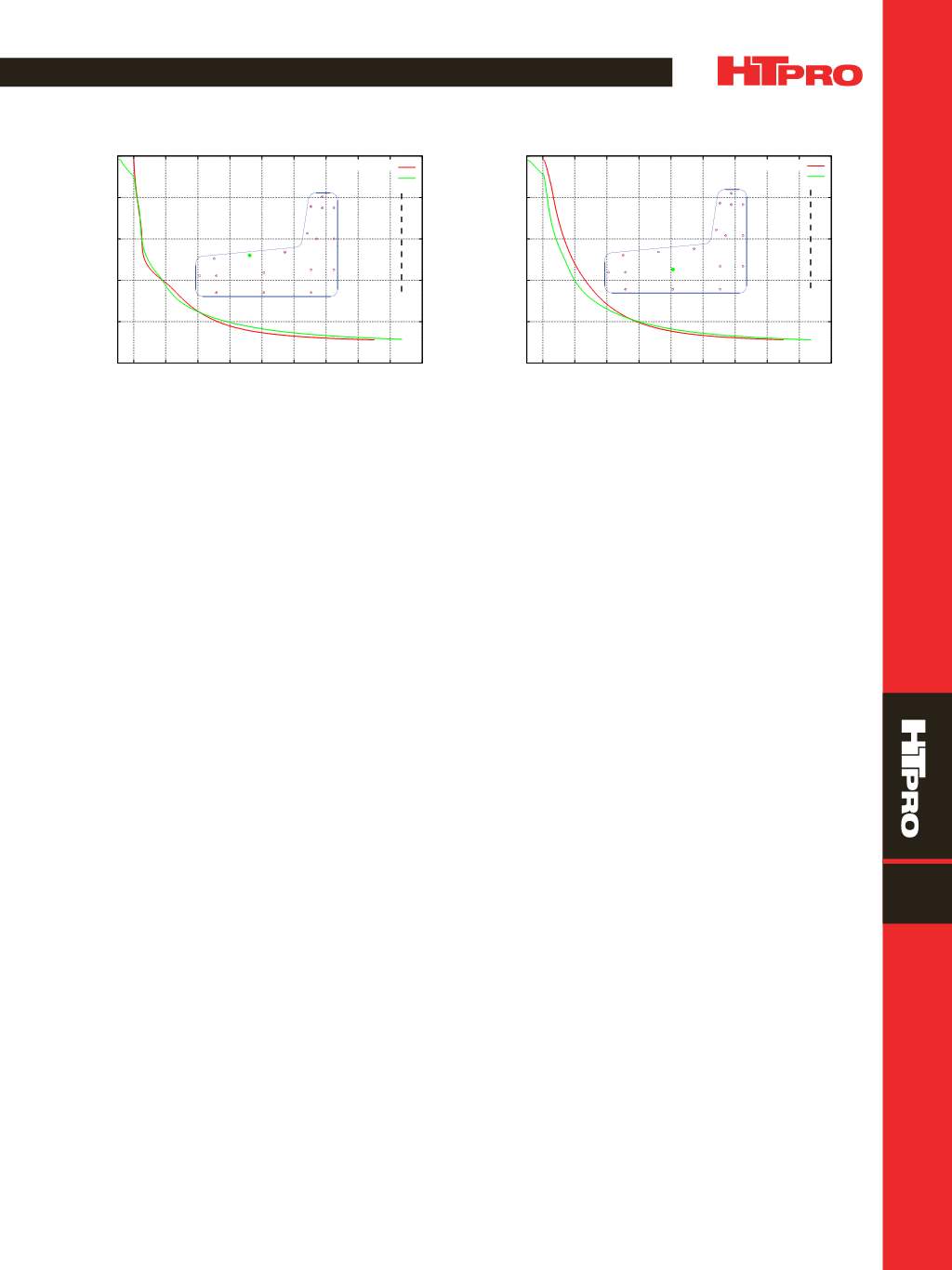

Cooling curves for locations with the least and great-

est average deviations are shown in Figs. 3 and 4. The

curves in Fig. 3 are in close agreement over the entire cool-

ing range. The agreement in Fig. 4 is not as good, but it still

predicts overall cooling behavior fairly well. The location

of the greatest deviation in a buried thermocouple is curi-

ous, and may suggest a difference between simulated and

actual thermal properties of Inconel 718.

CONCLUSION

A method has been developed combining carefully

collected flow boiling heat flux data with CFD simulations

to provide accurate simulations of quenching operations.

A comparison of simulated and experimentally measured

cooling rates for a non-trivial geometry has shown good

correlation, indicating that this tool provides a practical

method of assessing and improving industrial quenching

operations. The level of correlation shown in the example

indicates that the experimental database is not limited to

the original test conditions (as with typical quench trials),

but rather has broad applicability.

~HTPro

Acknowledgments

This material is based on work supported by the United

States Air Force under Contract No. FA8650-12-C-5110. Any

opinions, findings, and conclusions or recommendations

expressed in this material are those of the author(s) and

do not necessarily reflect the views of the United States Air

Force. Airflow Sciences would also like to thank members of

the Air Force Research Laboratories Nickel Residual Stress

FEP program (United States Air Force Contract No. FA8650-

13-2-5201) for their collaboration on work related to the ge-

neric turbine disk shape.

Reference

1.

Edward B. Coy, Measurement of Transient Heat Flux

and Surface Temperature Using Embedded Temperature

Sensors,

Journal of Thermophysics and Heat Transfer,

Vol 24, No. 1, 2010.

For more information:

Andrew L. Banka is technical direc-

tor of Airflow Sciences Corp., 12190 Hubbard St., Livonia,

MI, 48150, 734.525.0300,

abanka@airflowsciences.com,

www.airflowsciences.com.

Centerline (not to scale)

0

200

400

600

800

1000

0 200 400 600 800 1000 1200 1400 1600 1800

Temperature (C)

Time (s)

Simulation

Experimental Data

Fig. 4 —

Location with poorest correlation for still oil generic

turbine disk.

0

200

400

600

800

1000

0 200 400 600 800 1000 1200 1400 1600 1800

Temperature (C)

Time (s)

Simulation

Experimental Data

Centerline (not to scale)

Fig. 3 —

Location with best correlation for still oil generic turbine

disk.