FEATURE ARTICLE

iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y / M A R C H

2 0 1 7

3 7

5

iTSSe

TSS

A

erospacecoatingsare the first formof protectionagainst

the extreme environments an aircraft is subjected to.

Therefore, a coating must maintain high performance

properties throughout its lifetime. A great deal of research is

taking place into the replacement of hexavalent chromium—

Cr(VI)—a carcinogen currently used within primers and as part

of the pretreatment for a coating substrate due to its highly

effective anticorrosive and adhesive properties. To minimize

exposure to Cr(VI), preventing topcoat degradation should

also be a priority. Measures taken to prolong topcoat lifetime

or identify when the topcoat is failing will aid in reducing the

risks imposed by Cr(VI). However, two main issues must first

be resolved. One is determining the degradation mechanism

at themolecular scale. This is essential in order to establish the

topcoat’s failure point. The other is monitoring the topcoat in

order to establish where the coating is in its functional lifetime

and whether measures should be put in place to aid function-

ality. This kindof large-scalemonitoring requires a simple, cost

effective, and nondestructive technique.

First, inorder tounderstand thedegradationphenomena,

it is essential to examine the interface between the topcoat

and the environment. Themain causes of degradation include

high humidity, extreme temperatures, and UV radiation, which

is an acute cause. Many well established testing methods exist

within the coatings industry as ameans of comparing coatings

and meeting application requirements. These include natural

exposure and accelerated testing methods such as exposure

within a QUV chamber, prohesion chamber, and temperature

cycling. However, thesemethods often requiremonths or even

years of exposure to observe degradative effects. Further, as an

aircraft crosses the tropopause the level of ozone it is exposed

to rises significantly, an issue seldom addressed in the liter-

ature but that could play a vital role in determining an aero-

space coating’s failure mechanism. With this in mind, a novel

coating test method called HyperTest was developed, which

combines UV and ozone—a technique traditionally used for

secondary electronmicroscopy sample preparation.

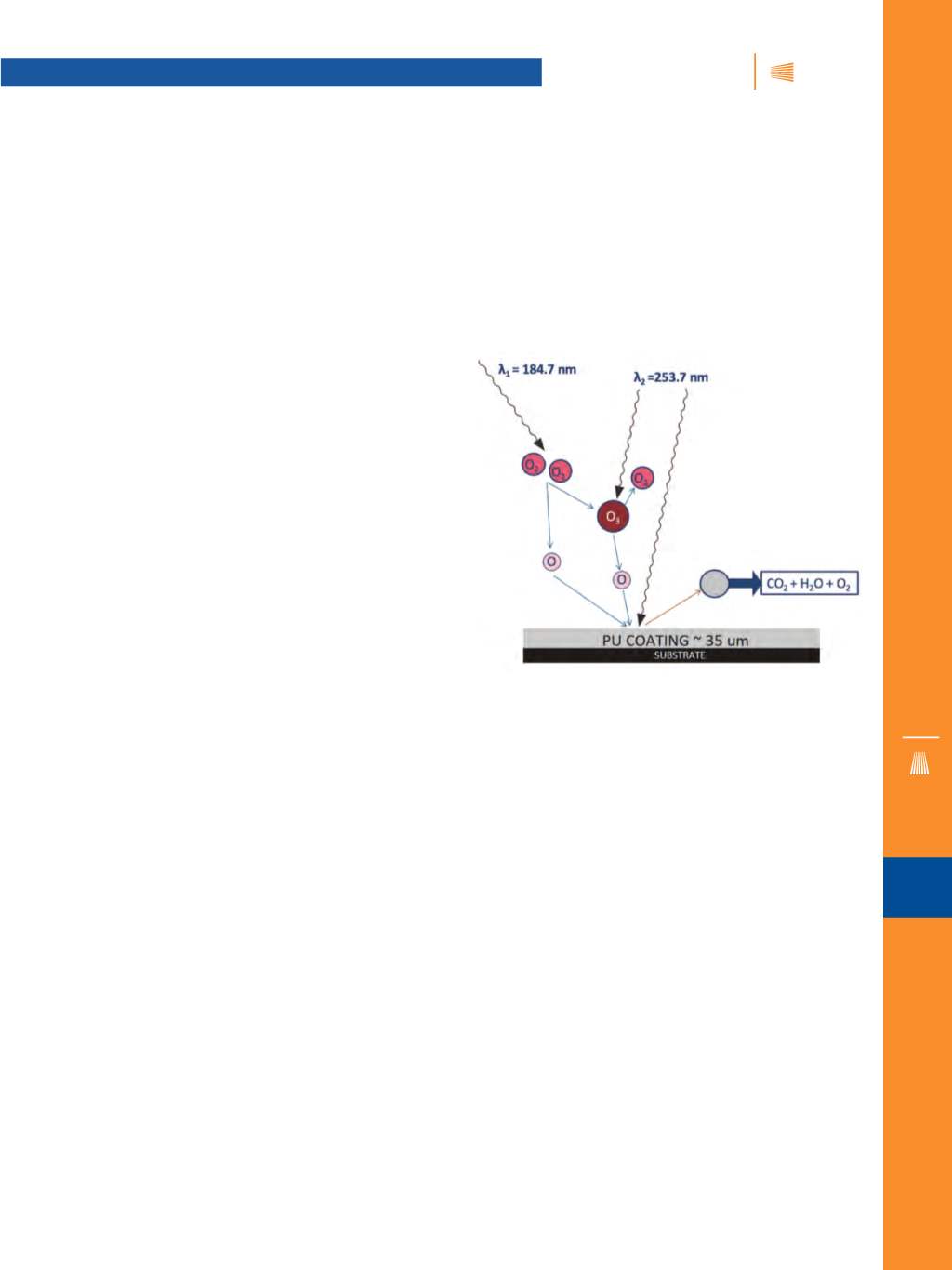

The device requires the sample to be placed within a vac-

uum chamber and then uses a UV lamp light source at wave-

lengths (λ) of 185 and 254 nm to irradiate the topcoat surface.

The long wavelength is also able to photodissociatemolecular

oxygen into atomic oxygen, which is then able to form ozone.

The short wavelength penetrates the coating surface creating

HYPERACCELERATED DEGRADATION OF AN

AEROSPACE COATING

A promising method of testing aerospace coatings could help minimize exposure

to hexavalent chromium by understanding coating lifecycles.

Taraneh Bozorgzad Moghim, Marie-Laure Abel, and John F. Watts

University of Surrey, UK

excited molecules or free radicals, which are able to react with

ozone to form simple volatile molecules that are released by

the vacuum (Fig. 1). Through analysis of the topcoat of the

UV/ozone exposed samples, as detailed here, the HyperTest

method proves to be hyperaccelerating when compared to

samples treated with UV within a QUV chamber.

ANALYZING COATING FAILURES

Surface sensitive analytical techniques are imperative for

understandingdegradationphenomena.Determiningchanges

occurring to the topcoat surface, particularly during initial deg-

radation, can aid development of a degradation mechanism

and subsequently allow identification of the coating’s failure

point. The main analytical techniques applied in this research

include time of flight secondary ion mass spectrometry (ToF-

SIMS) and x-ray photoelectron spectroscopy (XPS), recorded

using a Theta Probe spectrometer (Fig. 2). ToF-SIMS provides a

significant level of elemental andmolecular detail of the upper

monolayer of the surface, enabling identification of degrada-

tion products. XPS is also a highly surface-sensitive technique,

offering chemical state information and enabling quantita-

tive analysis. XPS helps facilitate monitoring of degradative

changes, which occur as a function of UV and UV/ozone

exposure.

Fig. 1 —

Schematic detailing the functionality of the HyperTest

method using UV/ozone.